Feed Manufacturing Process

- The Feed Manufacturing Process and Machines have evolved and refined after years of operation in various countries including India.

- From Manual operations of the Plant, the operations were slowly converted to Automated Operations, starting with Batching System and then to Full Automation of the Plant.

- This has improved productivity, reduced manual intervention at various stages and resulted in utilizing the full capacities of the Machines.

- The Mash production from the earlier times has been shifted now to full Pellet Production.

- This has improved quality of the end Product and reduced wastage. The Process of Production now has clearly defined sections as:

OUR PRODUCTS

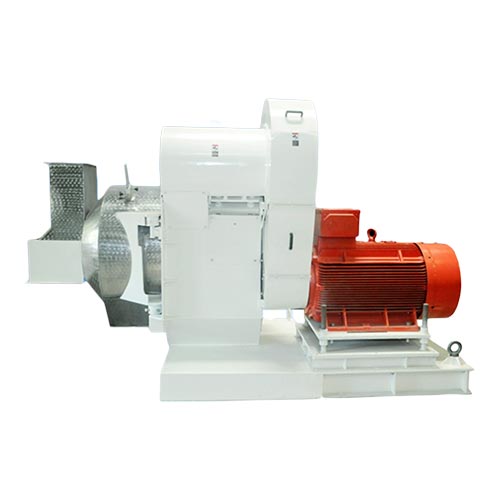

Hammer Mills

- We manufacture Hammer Mills of Capacity 1 TPH to 25 TPH on a 4 mm hole sieve.

- We supply the Hammer Mills with suitable aspiration units.

Batch Mixer

We make Single Shaft Ribbon & Paddle Mixers of capacities 500 Litres to 10,000 Litres And Double Shaft Paddle Mixers of 500 Litres to 5000 Litres.

- Provision for liquid addition can be given on request.

Molasses Mixers

- We manufacture molasses mixer of capacities of 5 TPH to 25 TPH.

- Our machine can take a maximum of 20% molasses.

- A provision for steam addition is included.

- Our units have differential speed rotor system.

- An exclusive CEASPL design.

Pellet Mills

- Pellet Mills of capacities ranging from 1 TPH to 25 TPH on 8 mm hole size dies are supplied by us.

- We manufacture Vee Belt Driven Units and Gearbox Driven Units.

- The machines are of high capacity, and have less running cost units.

- We also manufacture Laboratory Pellet Mills of 200 kg per hour capacity.

Pellet Cooler

- Our Pellet Coolers can handle pellets from 3 TPH to 30 TPH.

- All our Pellet Cooler systems are matched with our Pelleting Lines.

Pellet Sieves

- We manufacture Pellet Sieves to handle pellets from 3 TPH to 30 TPH.

- This is a vibratory single deck unit.

- Multi Deck units and circular sieves can be supplied.

Twin Rotor Jute Twine Remover

- Our machine fitted after the intake elevator can process mash at the rate from 10 TPH to 60 TPH.

- Our machines are designed to catch the jute strings from the raw material.

- An exclusive CEASPL design.

Plant Automation and Control Center

- We do simple batching system controls to full plant automation with Scada Screens.

- The entire Feed Plant can be operated from the control room with minimum number of operators, with full automation controls.

- Various operating reports can be generated from our System.

Feed Mill Spare parts

- We regularly supply spares for the Feed Mills in India and Overseas.

- Dies, Press Roll Shells, Hammer Mill Beaters and Hammer Mill Sieves are supplied by us.

- We have Spares for all makes of machines.

- These parts have long life which reduces downtime for replacement of these.

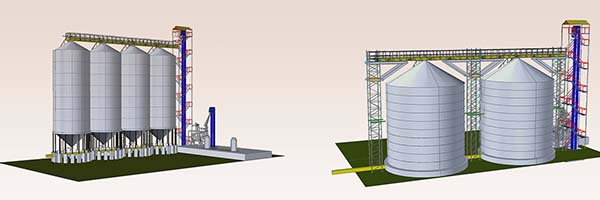

Silo Storage Systems

- Silos are available as Flat Bottom Silo and Hopper Bottom Silo.

- Earlier the Silos were used mainly for storage of grains. The grain’s specific weight was taken for determining the capacity of the Silos.

- Now the Silos are used for storing large quantities of De-oiled Rice Bran, Soya Extraction and all other De-oiled cakes. The Flat Bottom Silos for De-oiled Rice Bran, Soya extraction and other powdery material have special discharge system, for storing large quantities of material. The Hopper Bottom Silos are used for storing De-oiled cakes in lesser quantities.